SWIR335KMB-U200 Short-Wave Infrared Camera

Product Introduction

SWIR335KMB-U200 uses advanced CQD quantum dot sensor technology, achieving a 400-1700 nm ultra-wide spectral response. With a 200 fps high frame rate design and deep TEC cooling system, it significantly enhances low-light imaging performance. The USB 3.0 interface ensures high-speed data transmission, while the 512 MB buffer guarantees stable image acquisition. Suitable for high-speed inspection, scientific research, semiconductor detection, spectral analysis, and other high-end applications.

Key Features

- 400-1700 nm ultra-wide spectrum CQD sensor

- 0.33 MP resolution, 640×512 pixels

- Deep TEC cooling, 40 °C below ambient

- 15 µm large pixel size

- 200 fps @ 640×512 ultra-high frame rate

- 40% quantum efficiency

- Global shutter technology

- USB 3.0 high-speed interface

- 12/14-bit selectable ADC

- 512 MB large capacity buffer

- Optically isolated IO interface

- Support for external trigger control

- Multi-platform SDK support

- OEM customization service available

Product Details

| Specifications | |

| Model | SWIR335KMB-U200 |

| Sensor | China-made 640×512 (CQDs) |

| Shutter Type | Global Shutter |

| Color Type | Monochrome |

| Resolution | 0.33 MP (640×512) |

| Sensor Size | 9.60 mm × 7.68 mm |

| Sensor Diagonal | 1/1.3" (12.29 mm) |

| Pixel Size | 15 µm × 15 µm |

| Spectral Response Range | 400–1700 nm |

| Performance Parameters | |

| Frame Rate | 200 fps @ 640×512 |

| Bit Depth | 12/14-bit |

| Dynamic Range | TBD |

| Sensitivity | 40% |

| Interface Parameters | |

| GPIO | 1 optically isolated input, 1 optically isolated output |

| Lens Mount | C-mount |

| Data Interface | USB3 |

| Power Supply | DC 12V power supply |

| Physical Parameters | |

| Dimensions | 68 mm × 68 mm × 90.3 mm |

| Weight | 485 g |

| Environmental Parameters | |

| Operating Temperature | -30 °C to +60 °C |

| Operating Humidity | 20% to 80% (non-condensing) |

| Storage Temperature | -40 °C to +85 °C |

| Storage Humidity | 20% to 80% (non-condensing) |

| Other Parameters | |

| Operating System | Win32/WinRT/Linux/macOS/Android |

| Certification | CE, FCC |

Product Overview

SWIR335KMB-U200 is a Short-Wave Infrared (SWIR) industrial camera based on the high-performance China-made 640×512 (CQDs) CQDs colloidal quantum dot sensor, featuring the following characteristics:

- Broad spectral response: covers the visible band through SWIR with a response range of 400–1700 nm.

- High-resolution imaging: delivers 0.33 MP (640×512) pixels with 15 µm × 15 µm pixel size, supporting frame rates up to 200 fps @ 640×512 while outputting 12/14-bit.

- Global shutter design: utilises Global Shutter to capture fast-moving scenes without tearing.

- Multiple interface support: offers USB3 connectivity, works with C-mount lenses, and supports ROI, trigger I/O, and binning controls.

- Compact design: compact dimensions (68 mm × 68 mm × 90.3 mm) with a weight of approximately 485 g simplify system integration.

- Cross-platform support: broad Win32/WinRT/Linux/macOS/Android compatibility, bundled SDK and ToupView software, and compliance with CE, FCC certifications.

Performance Parameters

Frame Rate

Up to 200 fps @ 640×512

Resolution

0.33 MP (640×512)

Dynamic Range

TBD

Application Areas

- Machine Vision and Industrial Inspection

- Scientific Research and Material Analysis

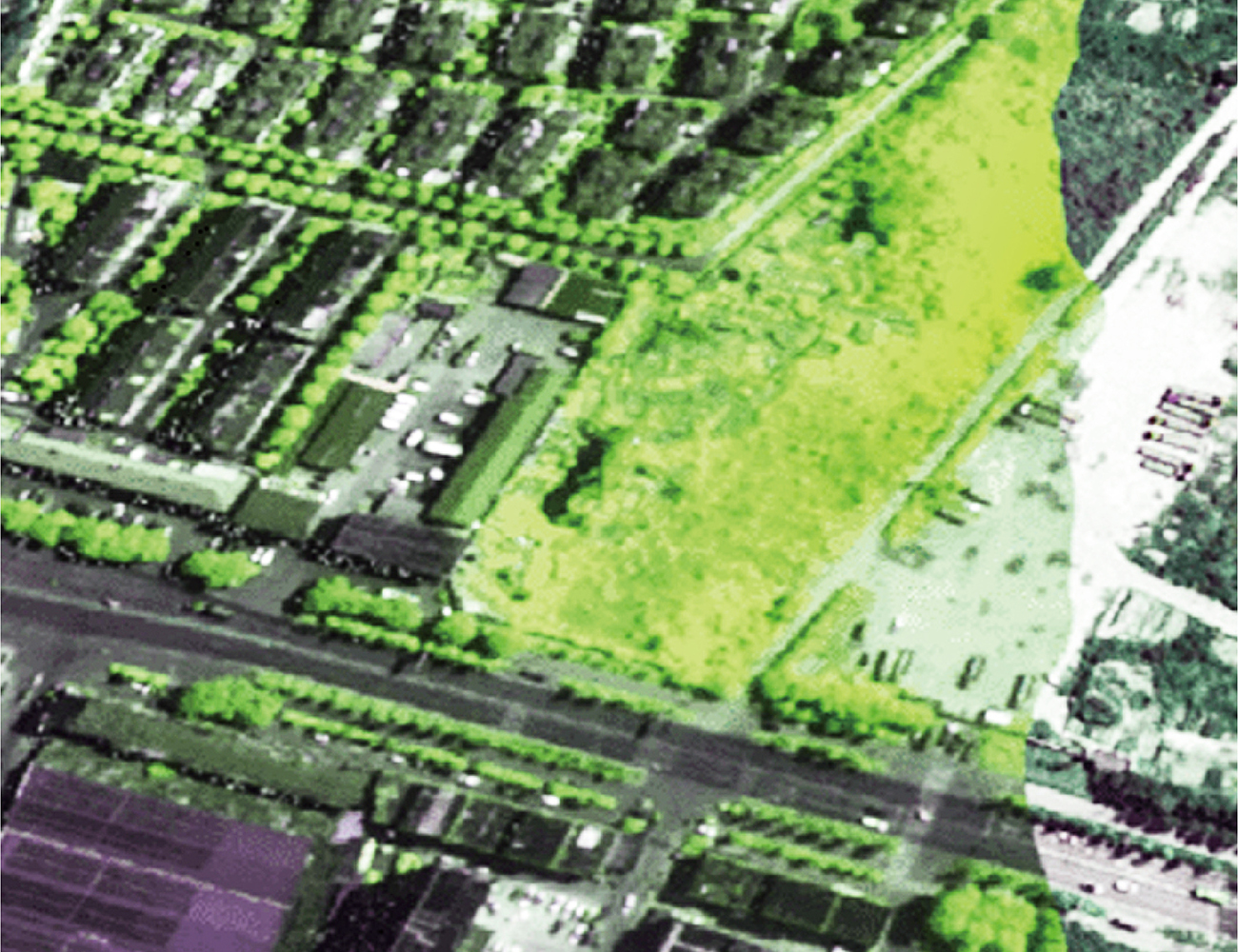

- Agricultural Spectral Remote Sensing Applications

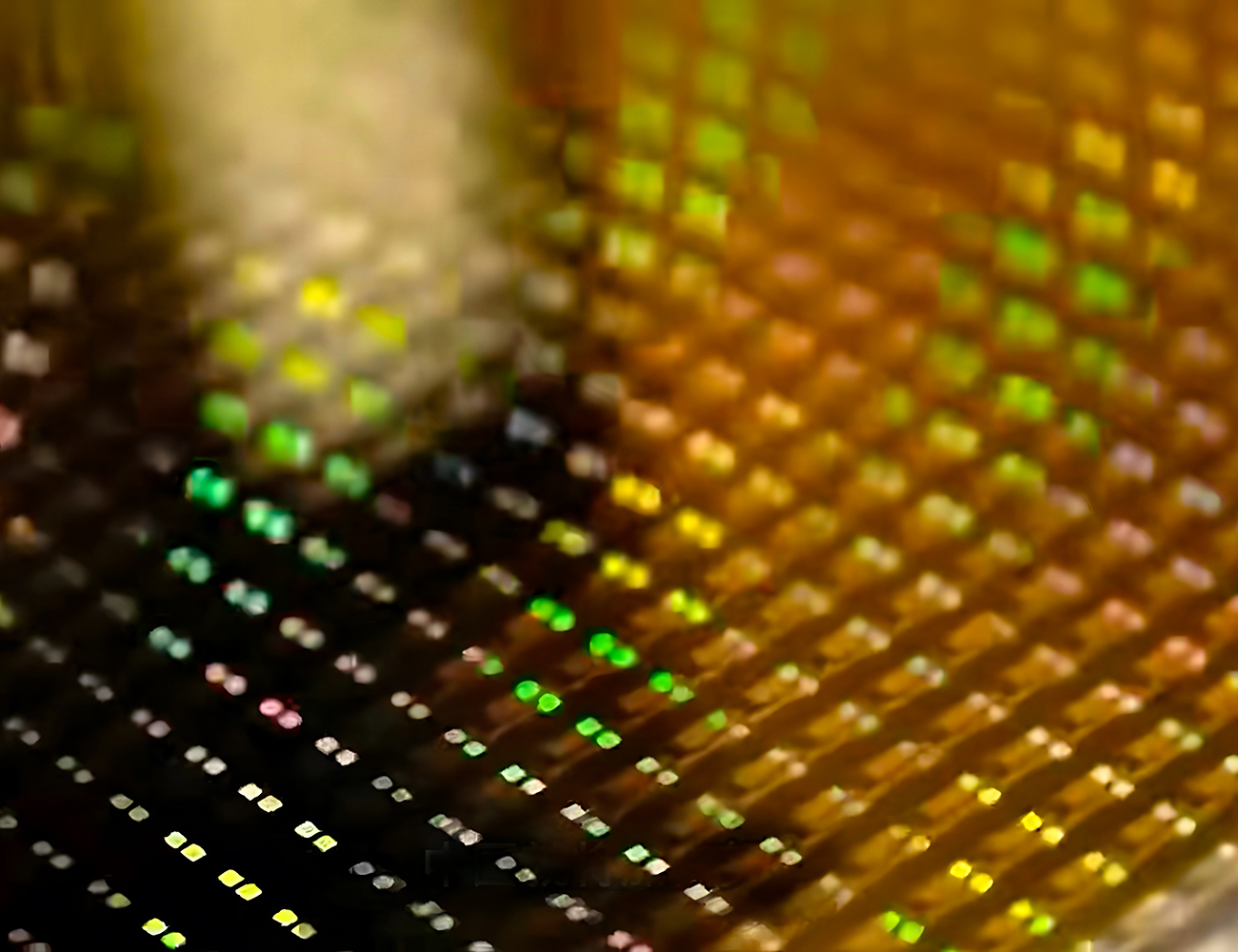

- Semiconductor Defect Detection

- Security Surveillance and Night Vision

- Food and Pharmaceutical Quality Inspection

Product Summary

The SWIR335KMB-U200 camera utilizes advanced CQD quantum dot technology, making it an ideal choice for industrial and research users. Its exceptional imaging performance, flexible spectral tuning capability, and stable cooling system can meet the demands of various complex application environments, advancing SWIR imaging technology from high-end research toward broader industrial and consumer-grade applications.

SWIR335KMB-U200 Product Manual

PDF format, includes detailed technical specifications and dimensional structure

CQD SWIR SDK Development Kit

Supports Windows, Linux, macOS and other platforms, includes CQD camera-specific API

ToupView Imaging Software

Professional imaging software, supports all functions and parameter settings of CQD camera

3D Model Files

STEP format, for mechanical design integration

Quantum Efficiency Curve #

Typical quantum efficiency response for the 300–1700 nm CQD cooled model

The official curve chart is for illustrative purposes only and shows SWIR335 typical quantum efficiency versus wavelength, response range: 400–1700 nm.

Packing List #

Standard configuration and packing details for the 300–1700 nm CQD series (USB3 · deep cooling)

- A 3-A instrument safety case: L: 28 cm W: 23.0 cm H: 15.5 cm (1 pc, ≈2.8 kg/box)

- B CQD 300–1700 USB interface camera

- C High-speed USB3 A-to-B gold-plated data cable (1.5 m)

- D 12 V / 3 A 6-pin aviation connector power adapter

- E Power cord

- F External trigger control cable (1 pc)

Product Dimensions #

Outline drawing of the USB3 cooled model (C-mount)

Frequently Asked Questions

Learn more about CQD SWIR colloidal quantum dot short-wave infrared camera technology

Deep Understanding of CQDs CMOS SWIR Cameras

CQDs CMOS image sensors are a new type of short-wave infrared (SWIR) imaging technology that uses Colloidal Quantum Dots as photosensitive materials and deeply integrates with standard CMOS processes. Compared to traditional InGaAs solutions, CQDs CMOS sensors offer advantages such as high cost-effectiveness, high resolution, compact size, suitability for large-scale mass production, and environmental friendliness, promoting SWIR imaging from high-end scientific research to broader industrial, agricultural, and consumer-level applications.

The absorption peak of CQDs materials can be flexibly customized by adjusting quantum dot particle sizes, enabling a single chip to cover a broad wavelength band from approximately 300–1700 nm or even extended to 2500 nm. Their quantum efficiency, dynamic range, and signal-to-noise ratio continue to improve, with some models capable of room temperature low-noise imaging and optional TEC cooling for high-requirement scenarios.

CQDs CMOS SWIR cameras feature standard optical interfaces and compact module designs for easy system integration and large-scale applications, making them ideal solutions for industrial inspection, material analysis, semiconductors, agricultural sorting, machine vision, food and pharmaceutical testing, and other fields.

Technical Features

Core advantages of CQDs CMOS SWIR technology

Wide Spectral Tuning Capability

By selecting different CQDs materials and particle sizes, sensitive response across 300–1700 nm or even broader wavelength bands can be customized to meet diverse application requirements.

High Cost-Effectiveness

Using standard CMOS large-scale manufacturing, unit costs are significantly lower than InGaAs solutions, suitable for batch integration and consumer-level applications.

High Resolution and Small Pixels

Supports high pixel density designs with fine image quality, facilitating detection of minute defects and details, improving inspection accuracy.

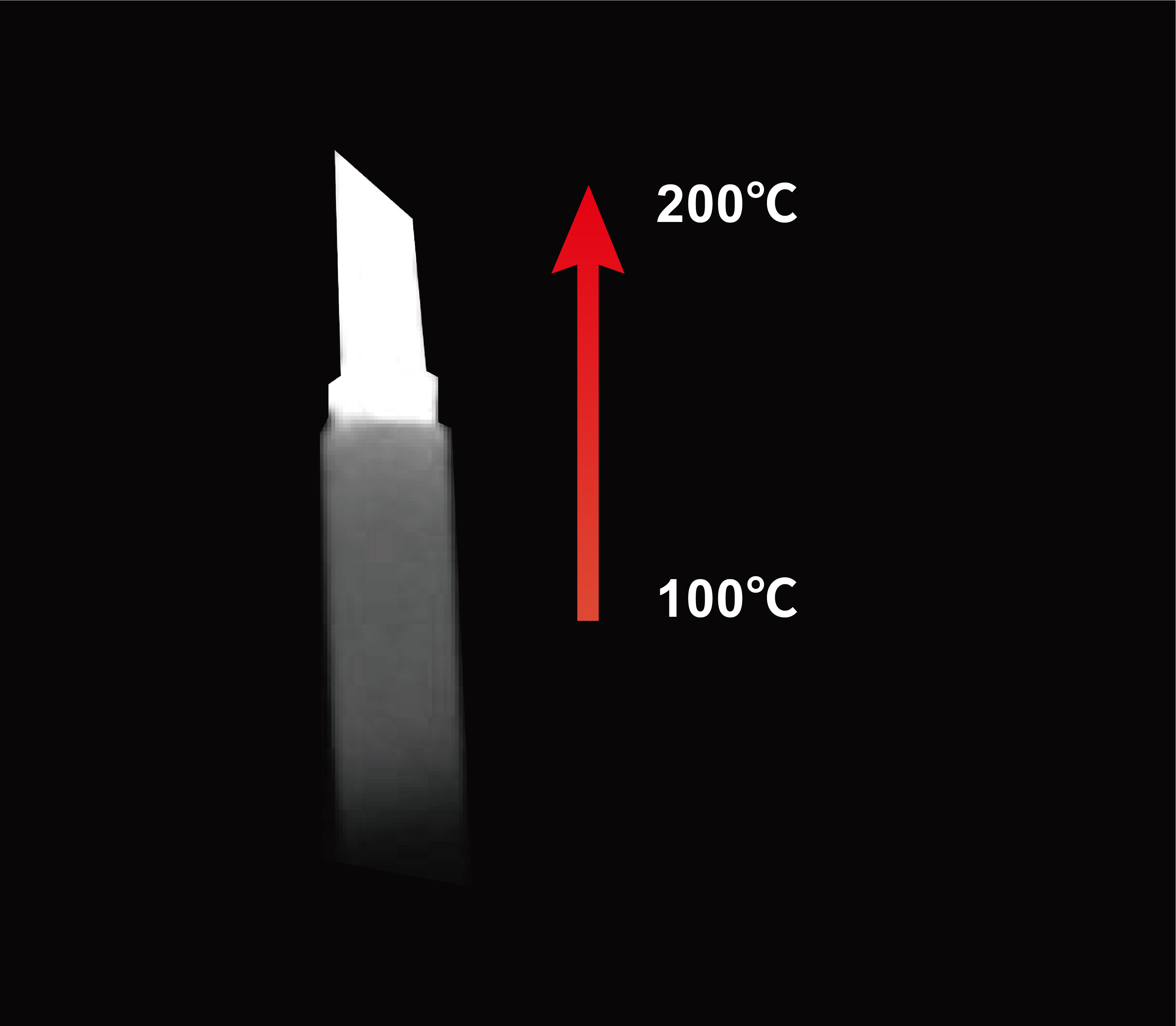

Room Temperature/Cooled Dual Mode

Supports room temperature low-noise imaging and optional TEC cooling for high-end scenario requirements, offering strong adaptability.

Environmentally Friendly

New-generation CQDs materials (such as Ag₂Te, InAs, etc.) comply with RoHS standards, meeting global market green compliance requirements.

Flexible and Easy Integration

Compact size and low power consumption, suitable for embedded devices and various intelligent terminal systems with high integration levels.

Application Scenarios

Wide application fields for CQDs CMOS SWIR cameras

Machine Vision and Industrial Inspection

Applied in semiconductor defect detection, plastic/food/pharmaceutical sorting, printing inspection, and other industrial scenarios, providing high-precision quality control solutions.

Complex Environment Imaging

Can still obtain clear images in scenarios where visible light is limited by haze, smoke, and dust, providing excellent environmental adaptability.

Material Sorting and Scientific Analysis

Suitable for precision material identification, scientific experiments, agricultural sorting, and other high-end applications, providing accurate spectral analysis capabilities.

Intelligent Sensing and Consumer Electronics

Suitable for embedding in intelligent terminals, expanding new applications such as night vision and non-invasive detection, promoting civilian adoption of SWIR technology.

Application Examples

Demonstration of CQDs CMOS SWIR camera applications in real-world scenarios

More Application Industry References

- Semiconductor Industry: Solar cell and chip inspection

- Agriculture: Spectral remote sensing applications via multirotor aircraft

- Recycling Industry: Material sorting of plastics, waste, and other materials

- Medical Imaging and Research: Hyperspectral and multispectral imaging

- Food Industry: Quality inspection and grading

- Beverage Industry: Liquid level detection in opaque containers

- Packaging: Seal inspection

- Glass Industry: High-temperature glass penetration defect detection

- Printing Industry: See-through hidden features

- Video Surveillance: Visual enhancement (e.g., smoke penetration)

- Security: Counterfeit detection, such as currency, wigs, or skin