Introduction

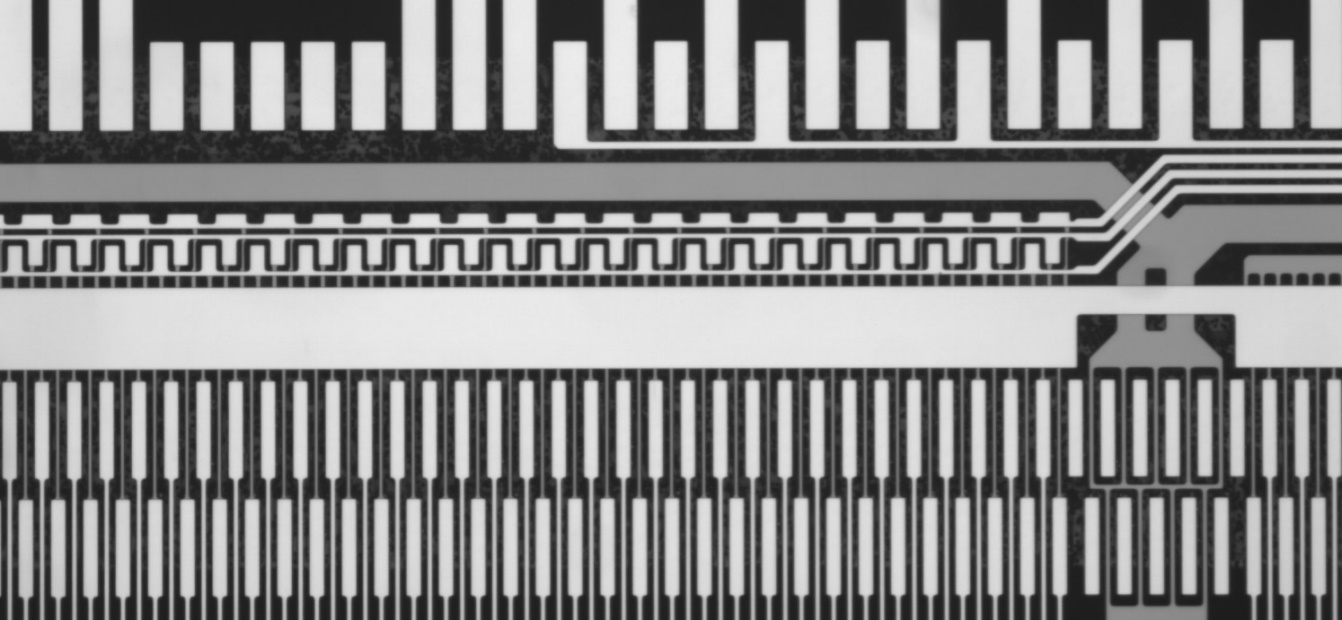

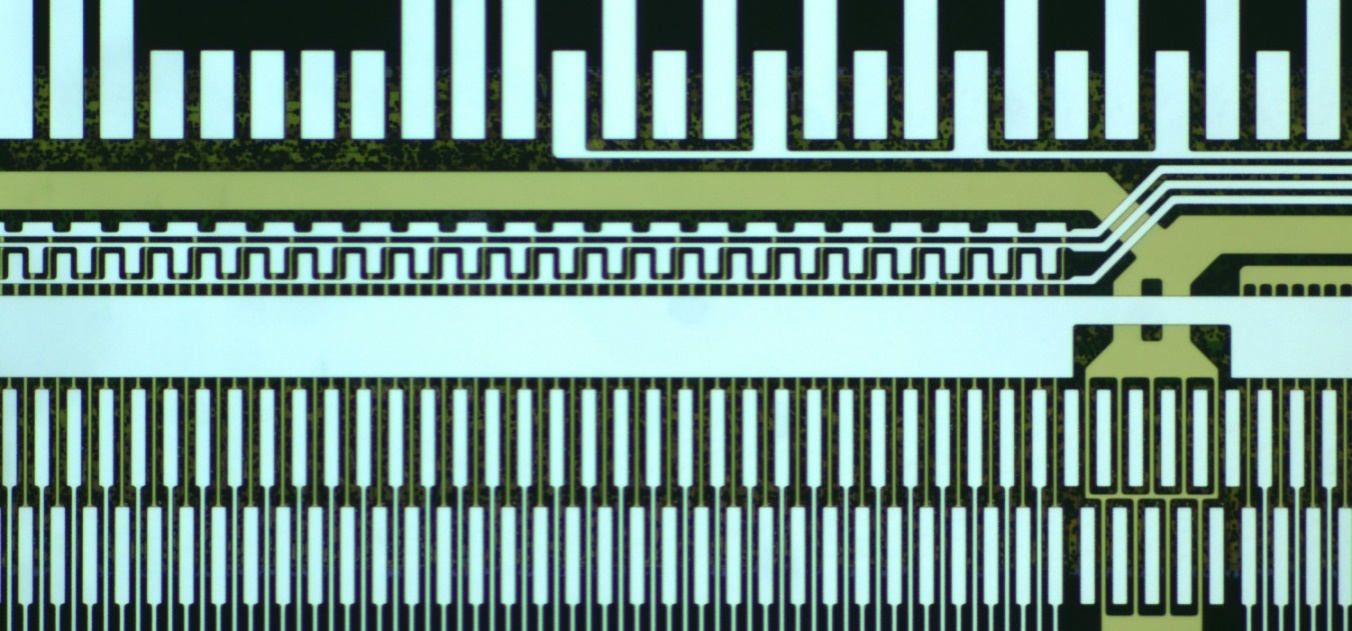

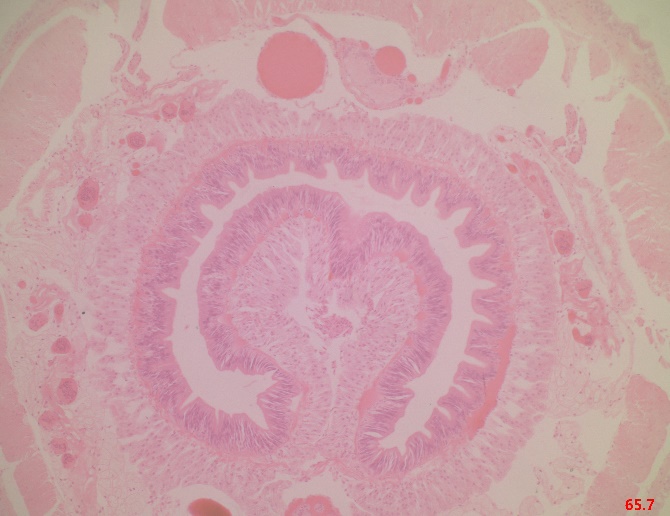

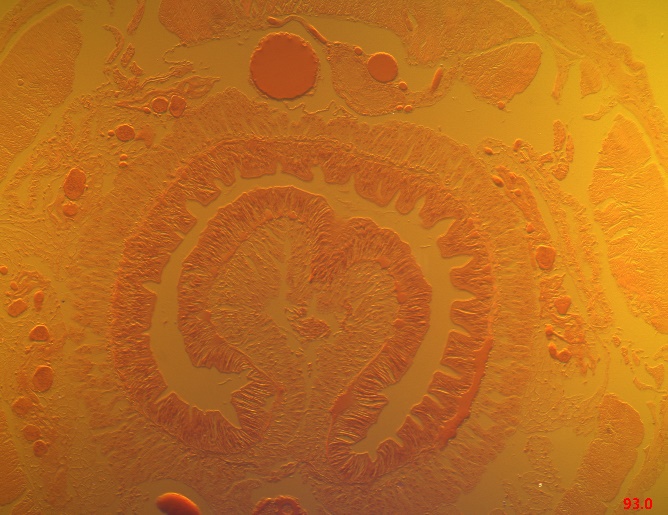

DIC100 Series Differential Interference Contrast Microscopy System

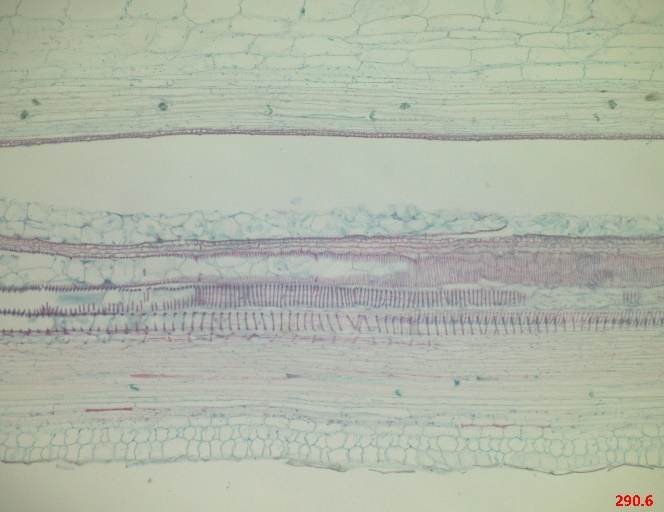

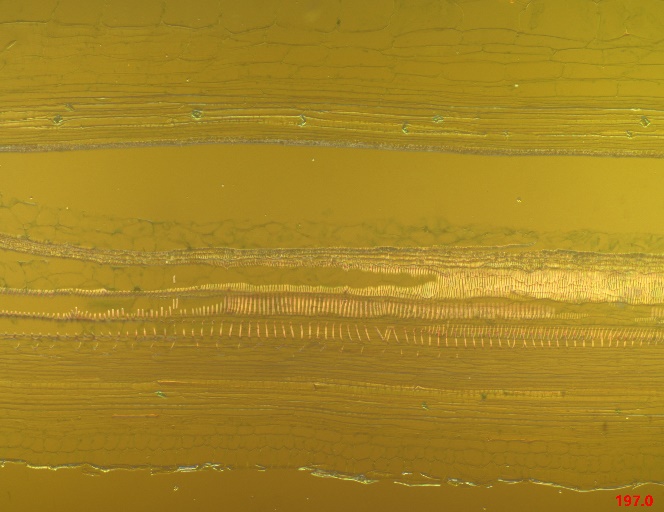

The DIC (Differential Interference Contrast) microscope system utilizes the principle of dual-beam polarized interference. The process is as follows:

1. The linearly polarized light from the polarizer passes through a Nomarski prism (which exhibits birefringence) and is split into two perpendicularly vibrating polarized beams with a certain phase difference;

2. After illuminating the sample, the slight surface unevenness or varying refractive indices in the field introduce an optical path difference between the two incoherent beams. These beams are then recombined by the Nomarski prism after reflecting off the sample;

3. The recombined light passes through the analyzer, aligning their vibration directions and creating interference;

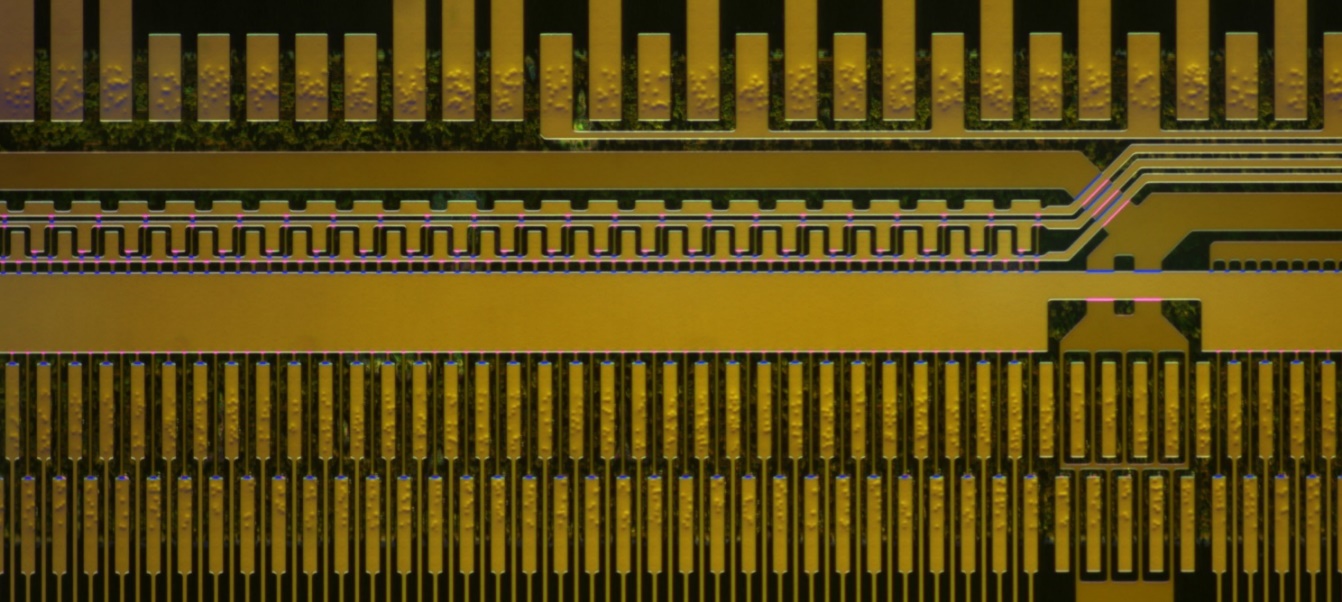

4. The sample details become enhanced in contrast due to interference and amplitude variations, rendering the image with a three-dimensional, relief-like effect.

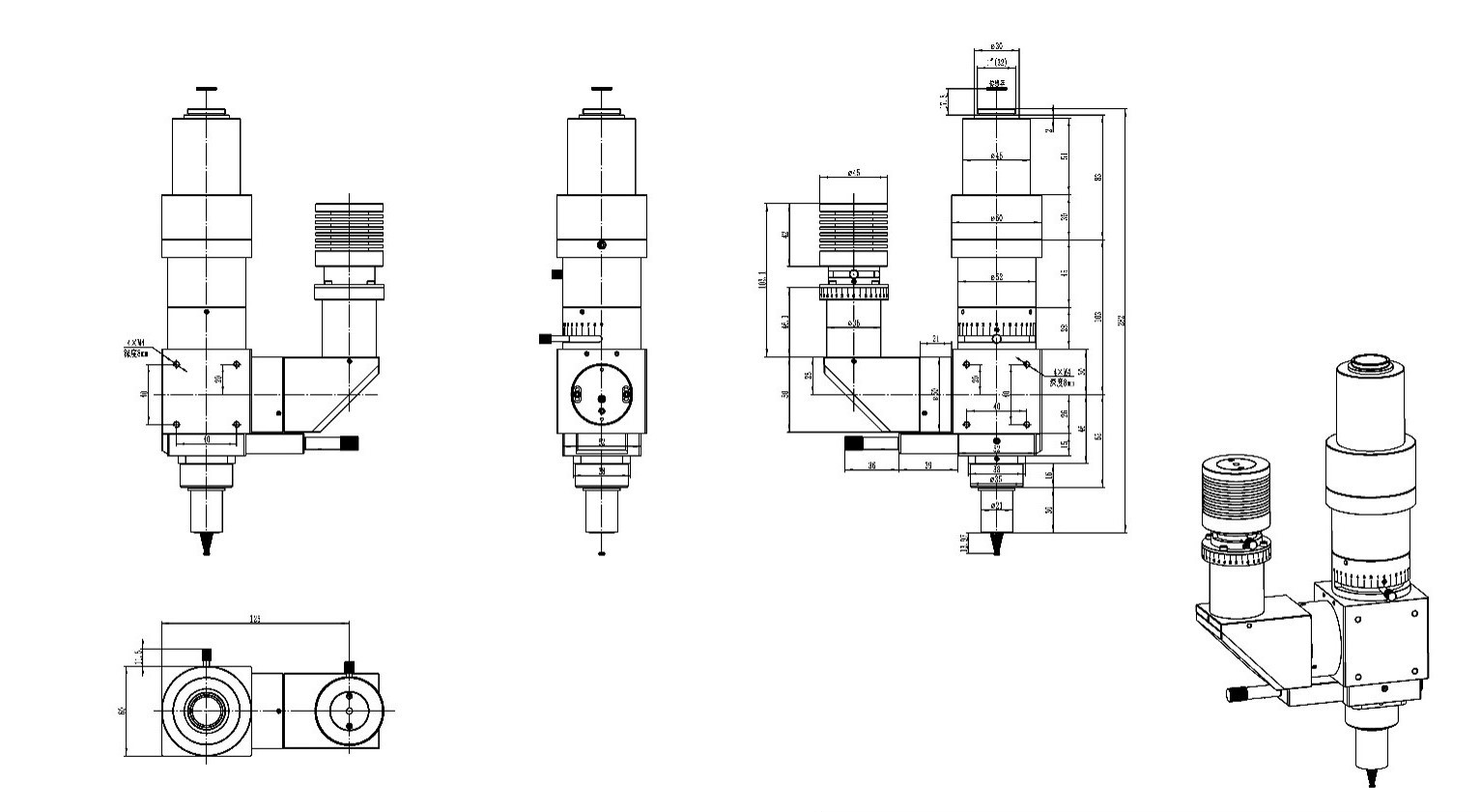

The Nomarski prism can be adjusted horizontally, functioning similarly to a phase compensator, which changes the brightness and interference colors between the object and background in the field of view to achieve the ideal observation effect. The left image shows the DIC100 series Differential Interference Contrast microscope system.

Key Features of the DIC100 Series Differential Interference Contrast Microscope System:

- Standard working distance series / long working distance series objectives (optional);

- Imaging optical path: 1X (tube lens focal length 180mm), with the option to customize various reduction lenses;

- Image plane size of the optical path: 25mm;

- Spectral range of the optical path: Visible light;

- Camera interface options: C/M42/M52, etc. (optional);

- Illumination options: Critical illumination / Köhler illumination (optional);

- Light source: 10W white/blue LED illumination (optional);

Standard Working Distance Objective Parameters (60mm parfocal, 200mm tube lens focal length)

Order code

Magnification

NA

WD/mm

Focal length(mm)

Resolution(um)

OFOV(mm)

IFOV(mm)

Thread

DIC2.5XA

2.5X

0.075

6.2

80

4.46

10

25

M26*0.705

DIC5XA

5X

0.15

23.5

40

2.2

5

25

M26*0.705

DIC10XA

10X

0.30

22.8

20

1.1

2.5

25

M26*0.705

DIC20XA

20X

0.40

19.2

10

0.8

1.1

25

M26*0.705

DIC50XA

50X

0.55

11.0

4

0.6

0.44

25

M26*0.705