BSM Series - Short-wave infrared microscope system

Product Introduction

The BSM modular SWIR microscope system is a next-generation Short-Wave Infrared imaging platform that extends the imaging range from the traditional visible band (400-700 nm) to 900-1700 nm. By combining high-sensitivity InGaAs sensor technology with dedicated M Plan Apo NIR objectives, it breaks through the optical barrier of silicon-based materials to deliver non-destructive, through-silicon inspection. The modular architecture integrates advanced illumination, imaging, and precision mechanics, providing micrometre-level subsurface defect detection capabilities for semiconductor manufacturing, materials science, and industrial inspection. Standard glass optics eliminate the need for costly reflective components, significantly lowering the technical barrier and overall cost for SWIR imaging.

Technical Features

Application Fields

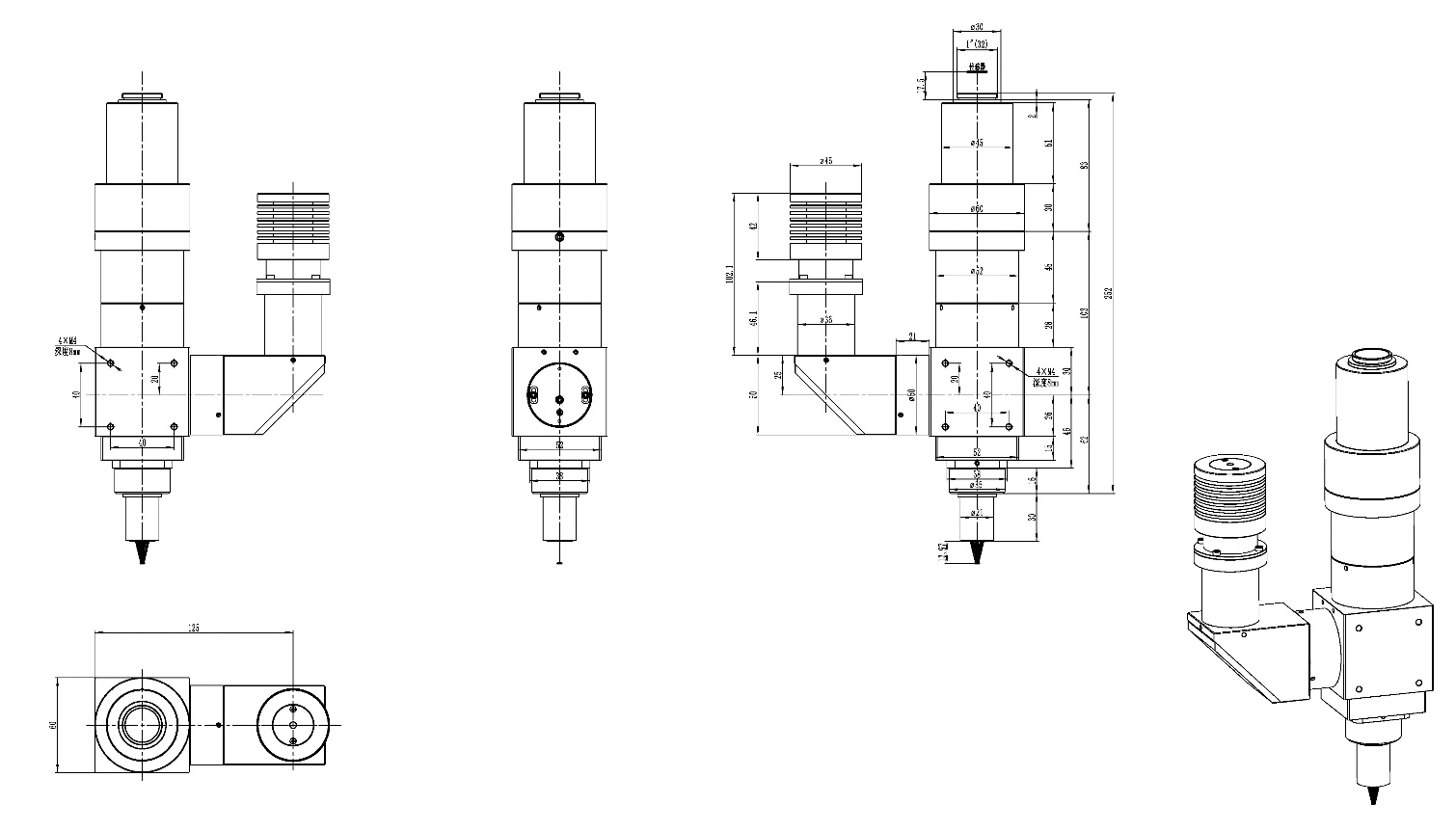

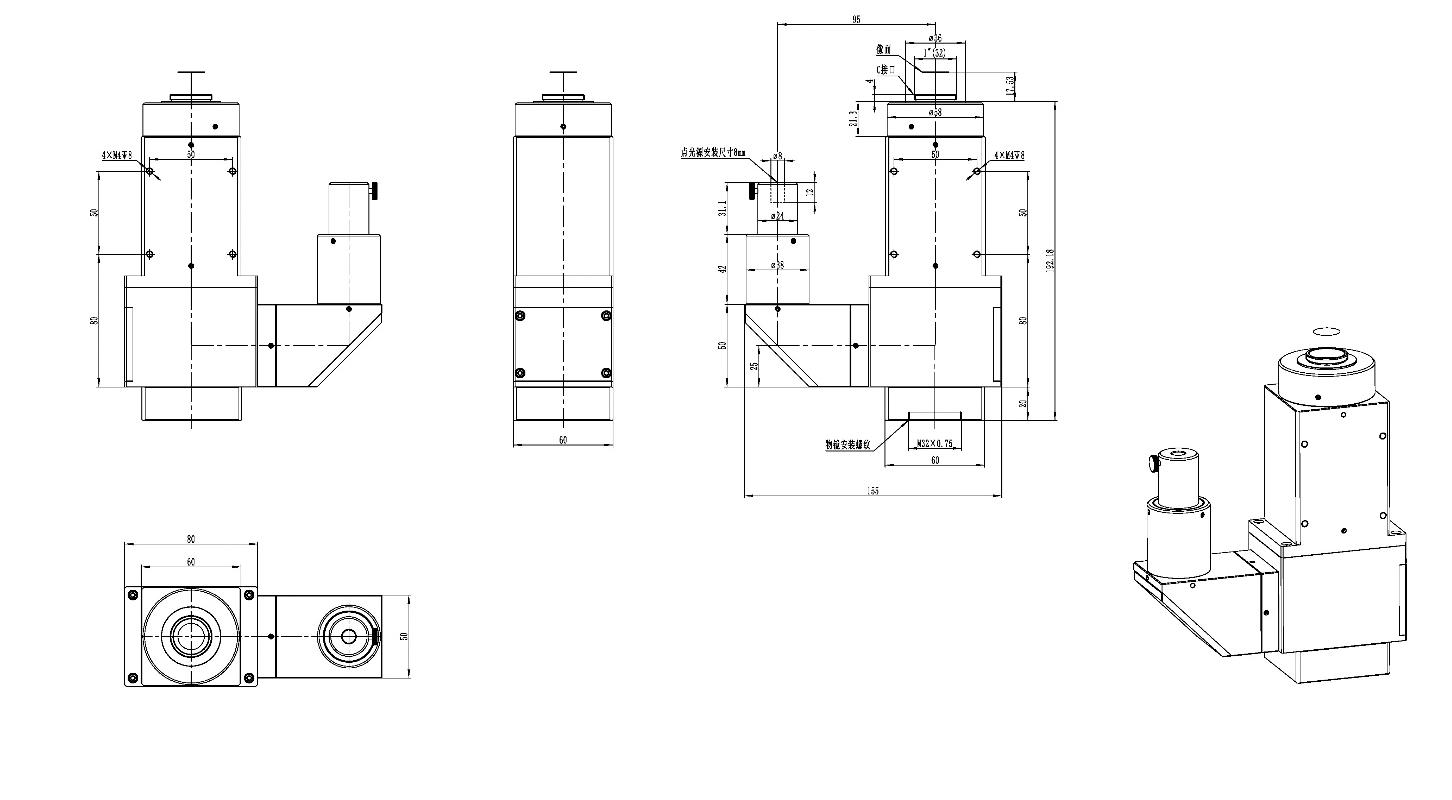

Product Details

Basic Technical Parameters

| Optical System Parameters | |

| Objective Series | Standard Working Distance Series / Long Working Distance Series (Optional) |

| Imaging Optical Path | 1X (Tube lens focal length 180 mm), customizable reduction lenses available |

| Image Plane Size | 25 mm |

| Spectral Range | Visible Light |

| Camera Interface | C/M42/M52 options available |

| Illumination System Parameters | |

| Illumination Method | Critical illumination/Kohler illumination options available |

| Light Source | 10W white light/blue light LED illumination options available |

Objective Parameters Table

System Configuration Solutions

Flexible combination of hardware and software modules based on application requirements

| Dimension | Key Configuration | Technical Highlights | User Benefits |

|---|---|---|---|

| Imaging Hardware |

• ToupCam X Series: IMX415/IMX571 back-illuminated CMOS, up to 45 MP, USB 3.0/HDMI 60

fps 4K • HCAM/PUM Portable Module: UVC plug-and-play, built-in 8 LED ring light |

• Low read noise & 66 dB+ dynamic range • Progressive scan + optional global shutter |

True color reproduction, high contrast; suitable for high-speed AOI, fluorescence weak signal detection and multiple scenarios |

| Zoom Optics |

• MZO Series (0.25×–8×): 20× zoom ratio, NA 0.12, 174 mm long working distance • ZOPE Integrated System: Built-in 8 LED & USB camera, parfocal linear zoom |

Dual-ended parallel optical path, diffraction-limited MTF, low distortion | Zooming without refocusing, transitioning samples from millimeter to micrometer scale |

| Illumination System |

• TZM0756DRL 65/85 mm LED ring light: PWM continuously adjustable brightness • TZM0756CL coaxial light + point light source • AALRL-200 large ring light: 300 mm uniform field of view |

Multi-channel/polarized/coaxial composite light; LED angle 30° adjustable | Solving PCB solder joint glare, wafer scratches, transparent film inspection and other challenges |

| Mechanical Platform |

• TPS-600 coarse and fine adjustment stand (5 kg load capacity) • TPS-300 precision fine adjustment 2 µm step • Motorized Z & XY platforms (optional) |

Anodized Class II aerospace aluminum, ball screw | Long-term 24×7 stable positioning, supporting autofocus and array scanning |

| Software & Algorithms |

• ToupView: Real-time measurement/annotation, depth compositing, HDR, polarization

demodulation • SDK/API: Windows/macOS/Linux/Android • AI Module: Defect classification, dimensional tolerance determination |

Secondary development + PLC/robot serial protocols | Rapid integration into MES/SPC quality systems, supporting edge computing and cloud synchronization |

System Advantages

Five core advantages building professional microscopy imaging platforms

Complete Ecosystem, Turnkey Delivery

Cameras, lenses, illumination, stands, and software all developed in-house. No need for multi-vendor procurement coordination, plug-and-play saves 60% integration time.

High Resolution + Large Depth of Field

45 MP ultra-clear CMOS + depth compositing algorithms provide micrometer-level depth-clear images within 30 mm field of view.

Multi-band & Low-Light Imaging

Supports white light, near-infrared, and polarization combinations with synchronized exposure of coaxial and ring lights; presents texture details even at 0.05 lux.

Flexible Expansion, Investment Protection

Standard C-Mount and GigE Vision/USB3 Vision protocols enable later upgrades to AI modules, automated stages, and multi-camera synchronization without replacing the main system.

Cross-Industry Implementation Cases

Application Cases

Successful implementation experience across multiple industries

Semiconductor Manufacturing

FPC/PCB Quality Control

New Energy Materials