UV Series Lenses

Product Introduction

UV Series Lenses is a professional imaging lens series designed specifically for the UV (200-1000nm) wavelength band. it is widely used in UV inspection, Fluorescence excitation, Materials analysis and other fields.

Product Features

Multispectral Machine Vision Lens Series Overview

Professional imaging solutions covering visible light, short-wave infrared, and ultraviolet full spectrum

Unified Optical Platform for Multi-band Imaging Requirements

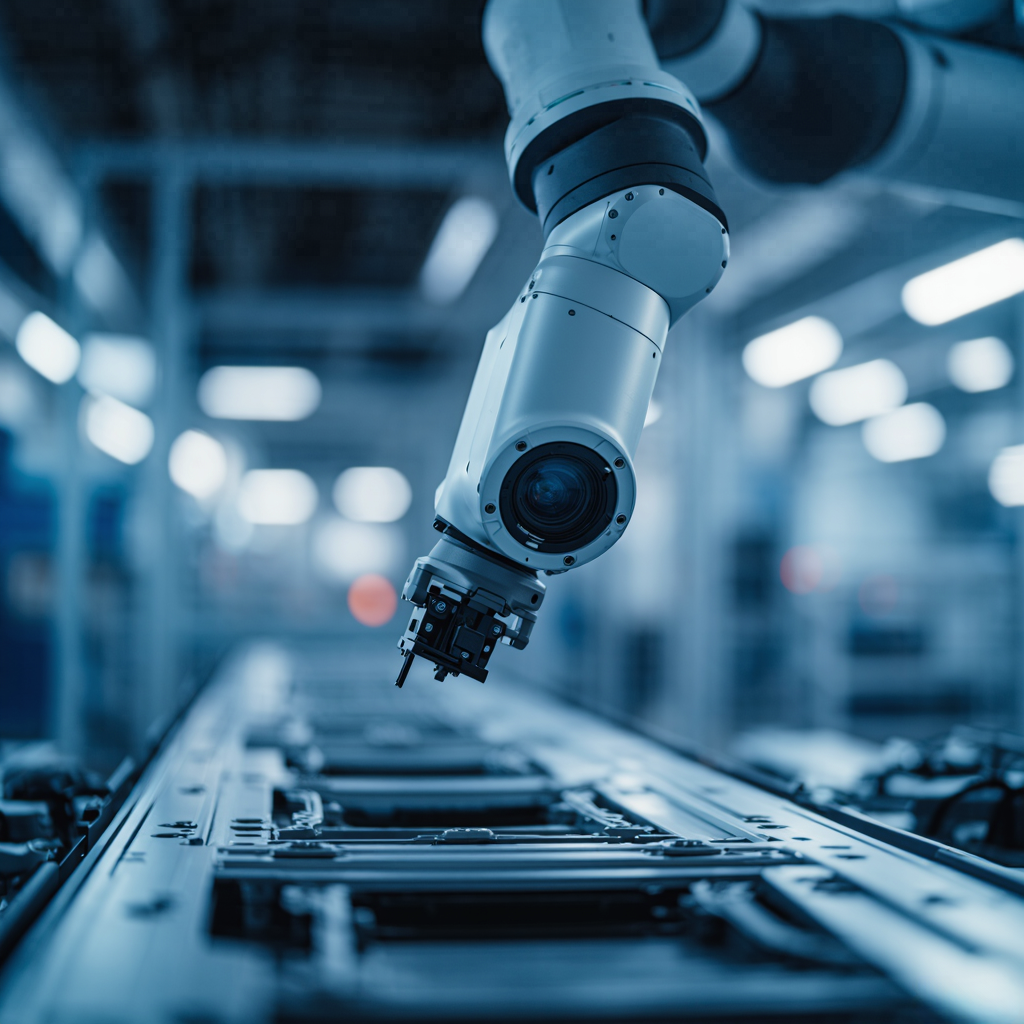

ToupTek Photonics multispectral machine vision lens series covers visible light (VIS), short-wave infrared (SWIR, 900–1700 nm), and ultraviolet (UV, 200–400 nm) multi-band imaging requirements, providing unified optical platforms for industrial inspection, scientific analysis, electronic semiconductors, and high-end machine vision systems.

The lenses use special glass and low-dispersion optical design with broadband coating processes to cover multiple wavelength bands in a single optical system, ensuring image consistency and low aberration. Compatible with C-Mount, F-Mount, and custom interfaces to meet multi-band application requirements of high-resolution industrial and scientific cameras.

In-Depth Technical Analysis

Professional optical design meeting multi-band high-precision imaging requirements

Full Spectrum Adaptation Capability

Professional Optical Processing

High Resolution and Multi-Interface Support

Wide Range of Applications

Why Choose ToupTek Photonics Multispectral Lenses?

Multispectral Integration

One lens meets VIS/SWIR/UV full-band imaging requirements, reducing equipment quantity and switching time

Low Aberration and High Transmission

Special glass and broadband coating ensure color consistency and high contrast

High-Resolution Industrial-Grade Design

Supports 20MP+, suitable for 2D/3D inspection and scientific imaging

Flexible Interfaces

C-Mount, F-Mount, and other multi-standard support for quick integration with existing systems

Product Details

Product Overview

The UV Series Lenses series lenses are specifically designed for UV (200-1000nm) wavelength band applications, using advanced optical design and coating technology to ensure optimal imaging performance within specific wavelength bands. This series features high resolution, low distortion, and high transmission characteristics, meeting various application requirements including UV inspection, Fluorescence excitation, Materials analysis .

Application Scenarios

UV inspection

Fluorescence excitation

Materials analysis

Core Advantages

UV Series Lenses Series Specification Comparison

| Model | Focal Length | Aperture | Resolution | Distortion | Mount | Manual |

|---|---|---|---|---|---|---|

| TPL-2528UV | 25 mm | F2.8-F32 | 100lp/mm | 0.40% | C | |

| TPL-5030UV | 50 mm | F3-F32 | 100lp/mm | 0.10% | C | |

| TPL-7538UV | 75mm | F3.8-F32 | 100lp/mm | -0.10% | C | |

| TPL-8528UV | 85mm | F2.8-F32 | 65lp/mm | 0.70% | F | |

| TPL-NV7838UV | 78mm | F3.8-F32 | 100lp/mm | -0.05% | C | |

| TPL-7838UV | 78mm | 3.8 | 0.10% | F |

Optical Performance Description

MTF Curve

The Modulation Transfer Function (MTF) is an important indicator for evaluating lens imaging quality, representing the lens's response capability to different spatial frequencies. Our lenses maintain excellent MTF values within the designed spatial frequency range, ensuring clear and sharp imaging results.

Chromatic Aberration Correction

Using special optical glass materials and advanced coating technology to effectively correct chromatic aberration, particularly in broadband applications, ensuring light of different wavelengths focuses on the same plane, reducing image blur caused by dispersion.

Distortion Control

Through precise optical design and processing technology, lens distortion is controlled at extremely low levels. Most models have distortion rates below 1%, with some high-end models achieving below 0.1%, meeting precision measurement requirements.

UV Optimized Design

Using UV-transmitting materials such as quartz glass with specialized UV anti-reflection coatings to ensure good transmission in the 200-400 nm ultraviolet band while maintaining visible light imaging performance.

Performance Guarantee

All lenses undergo strict optical performance testing before delivery to ensure each lens meets specified requirements. We provide detailed test reports and quality certificates.

Application Scenarios

Practical applications of multispectral lenses across various industries

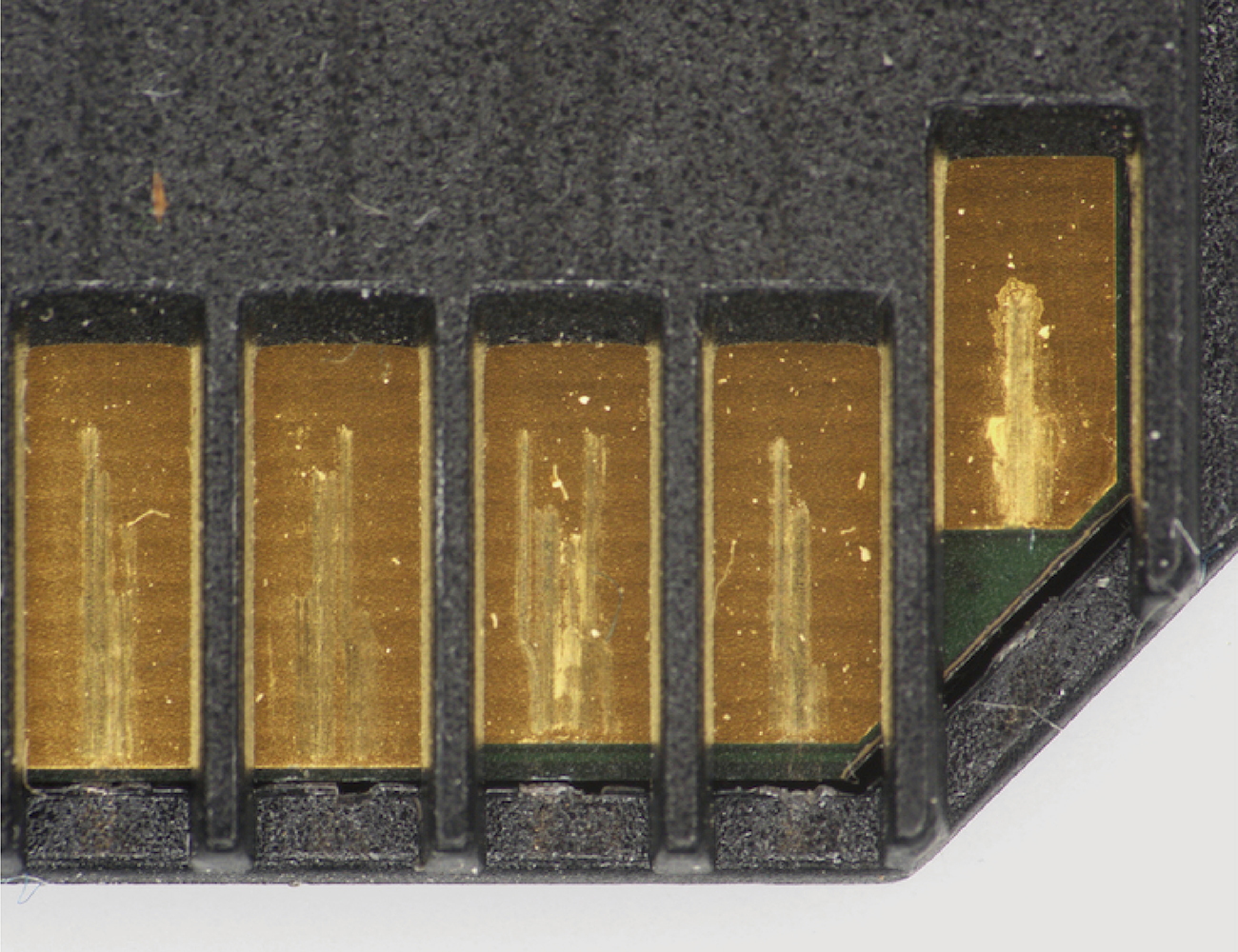

Semiconductor Wafer Inspection

Utilizing the SWIR wavelength band's ability to penetrate silicon materials for internal defect detection in wafers, combined with visible light for surface inspection, achieving multi-dimensional quality control with one system.

Materials Science Research

Multi-band imaging technology helps researchers observe material response characteristics under different spectra, providing important data support for new material development and performance analysis.

Industrial Product Quality Inspection

UV wavelength band enhances surface defect contrast, SWIR wavelength band detects internal structures, and visible light performs color and appearance inspection, ensuring comprehensive product quality.